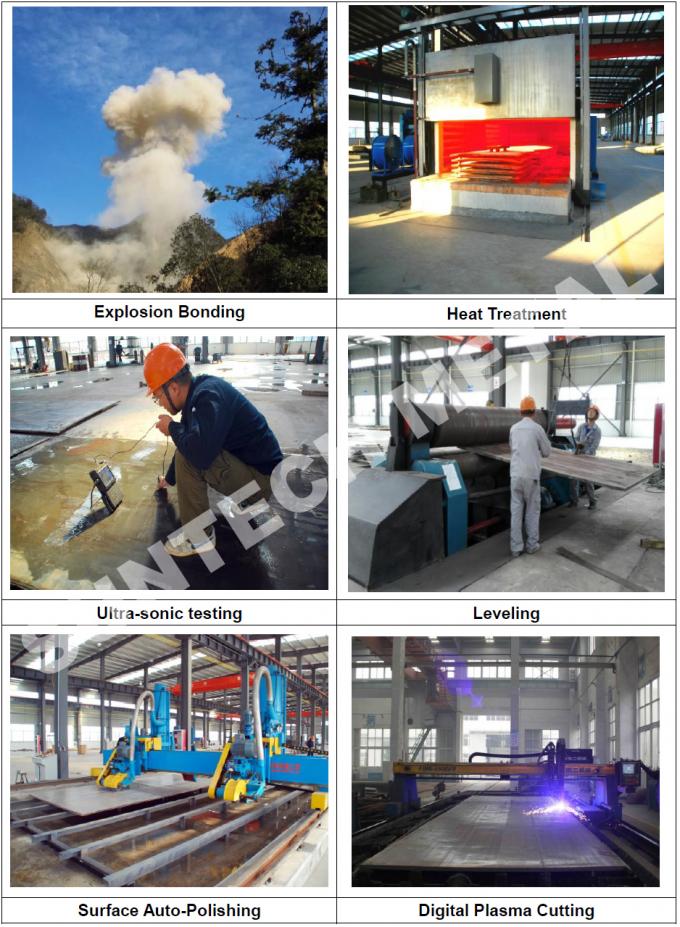

Production Line for Explosion Bonded Clad Plates and Heads:

Production Line for Chemical Process Equipment:

NANJING SUNTECH METAL PRODUCTS CO., LTD. is specialized at designing and fabricating pressure vessels and non-standard chemical process equipment and explosion bonded clad products of non-ferrous metals, such as Nickel Alloy, Titanium Alloy, Copper-Nickel Alloy, Zirconium, Tantalum Alloy, Super Stainless Steel and their clad materials. SMP’s main product includes Reactors, Heat-exchangers, Separators, storage tanks etc., which are widely used in such fields as petro-chemical, chemical, salt manufacturing, pharmacy, metallurgy, power, electronics, sea-engineering and environment protection, etc.

Our factory is entitled with Grade A1 for design, Grade A1 for manufacturing of pressure vessels and ASME U stamps authorization. Our factory is an ISO9001 company certified by National Quality Assurance Limited and awarded with three As of Credit Rating and High- tech enterprise. It is also a member of China Pressure Vessel Institute, China Non-ferrous Metal Institute, China Chemical Mechanical Equipment Institute, Jiangsu Welding Society and a supplier for China Petro-chemical Equipment and a recommended enterprise of Titanium and zirconium equipment by China Titanium, Zirconium and Hafnium Institute.

The total staff are 350 persons, among which, 22% are engineers specialized in designing, chemical and mechanical procedure, welding, heat treatment and non-destructive inspection. 37 welders with 252 qualifciations (including SAW, STAW, GTAW, GMAW) and 9 persons for non-destructive inspection (including PT,UT,MT,PT), who are qualified with China Code, including 13 welders with 49 items and 5 NDE persons are qualified with the requirements of ASME.

R & D Dep. is capable of designing drawings with CAD according to GB and ASME standards. It has such technique specifications and standards related to designing. The designers can timely communicate with the domestic and international design institutes or end-users by using internet and e-mail to transfer the drawings.

Manufacturing area is 14000m2(1st phase) and 15000 m2(2nd phase), among which, there are 1260M2 isolated workshop on non-ferrous metal welding. Non-ferrous metals and stainless steel are stored separately from ferrous metals per the requirement of Boiler and Pressure Vessel Manufacturing Requirement. Our factory also set up other important departments, such as No 1 & No 2 welding material rooms, welding lab, mechanical property lab, chemical analysis department and non-destructive inspection lab.

Rolling capacity is 80mm maximum and crane capability is 100 tons maximum. And, Our factory has more than 200 sets of manufacturing and testing equipments, such as automatic welding machine for tube joint, forming machines, cranes, cutting and shearing machines, heat-treating facility, detection equipment, mechanical property and chemical composition testing apparatus, PMI, ferrite test, coating thickness measure, Helium leakage test and other necessary tools.